Nonwoven Materials.

The world of fibres and nonwoven is vast, and the possibilities are endless. Our innovations are not limited by colours, textures, or materials. We believe that more is always possible. These samples, made using airlay technology and needlefelt processes, are just a glimpse of how creativity and innovation can drive real change, helping us shape a healthier planet.

AIRLAY TECHNOLOGY

1. Flame-Retardant Textiles Recycling

Some production waste in textile manufacturing is unavoidable, but that doesn't mean it's without value. Selvedges from woven fabrics are one of those unavoidable waste streams.

This sample consists of inherently flame-retardant fibres derived from selvedge production waste and binder fibres. It was processed into a nonwoven textile with the airlay and thermal bonding technology. Its flame-retardant and mouldable properties make it an excellent choice for acoustic and automotive solutions , providing both safety and style.

-

Acoustic

Automotive -

GSM: 2200

Thickness: 16mm

2. Post-consumer Textiles Recycling - airlay

Post-consumer waste is one of the most challenging streams for textile recycling. The mix of colours, finishes, and unknown fibres makes it complex—but not impossible. By transforming mainly viscose textile waste and binder fibres, we’ve created a vibrant, mouldable, nonwoven textile using airlay and thermal bonding technology.

The colourful character makes it an excellent choice for acoustic, interior, and packaging solutions.

-

Acoustic

Interior

Packaging -

GSM: 400

Thickness: 1mm

3. Polyurethane Foam Recycling

Polyurethane foam may seem like a challenge to recycle. Its rigid structure and thermosetting nature make traditional recycling methods difficult. With mechanical recycling, we can create durable, versatile, nonwoven materials.

This innovative process transforms foam, cotton, and binder fibres into a nonwoven textile using airlay and thermal bonding technology. Its bouncy and flexible properties make it an excellent choice for acoustic and furniture solutions.

-

Acoustic

Furniture solutions -

GSM: 750

Thickness: 25mm

4. Selvedge Recycling

In the world of textile production, some waste is simply unavoidable—like selvedges from woven fabrics. We turn selvedge production waste into an opportunity. This sample consists of inherently flame-retardant fibres from selvedge waste and binder fibres. Through airlay and thermal bonding technology, we have transformed these materials into a nonwoven textile that has not only flame resistance properties but is also moldable and paper-like in texture.

These characteristics make it an excellent choice for packaging, decorating, and labelling solutions.

-

Packaging

Decorating

Labelling -

GSM: 180

Thickness: 0,5mm

5. pattern spillage

Some waste in clothing production is unavoidable, and pattern-cutting waste is one of those streams. But with the right approach, even this byproduct can be transformed into something valuable.

This sample combines wool-cutting waste with binder fibres, processed using airlay and thermal bonding technology.

These characteristics make it a flexible, resilient, and sound-absorbing material. This nonwoven textile is ideal for acoustic solutions and furniture applications, proving that sustainability and performance can go hand in hand.

-

Acoustic

Furniture applications -

GSM: 1100

Thickness: 22mm

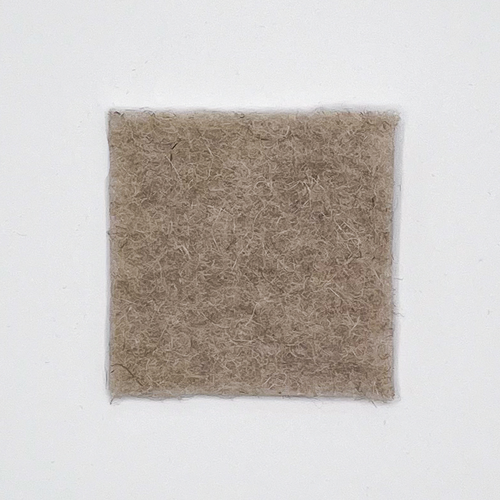

6. Hemp - airlay

Hemp is often prized for its nutritional benefits, but its stem holds incredible textile fibres. This innovative sample blends hemp and binder fibres using airlay and thermal bonding technology.

The result is a nonwoven textile that’s breathable, flexible, and mould-resistant. With these properties, it’s an ideal solution for building and automotive applications.

-

Building

Automotive -

GSM: 850

Thickness: 12mm

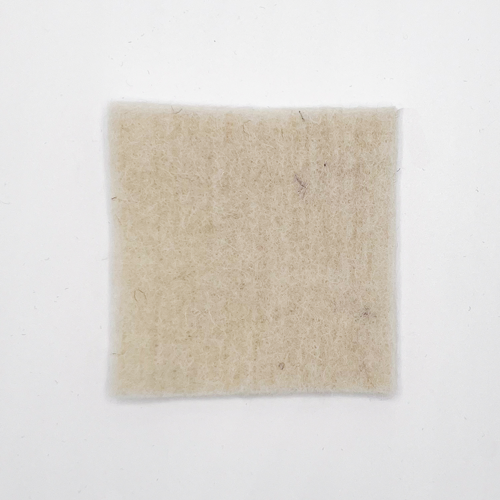

7. Swedish wool - airlay

Swedish wool is a highly underutilised resource, known for its outstanding natural qualities. One of its key advantages is its exceptional bounce and resilience, which allow it to maintain its shape while suspending a large volume of air. This makes it particularly effective for insulation, as the trapped air enhances thermal efficiency. When processed into a nonwoven using airlay and thermal bonding techniques, wool offers superior insulation and excellent fire resistance.

-

Insulation

Automotive

Acoustic -

GSM: 220

Thickness: 15mm

needle-punch TECHNOLOGY

8. HEMP - needle-punch

Hemp is usually valued for its nutrition, but its stem holds incredible textile fibres, too. We have taken hemp and binder fibres, transforming them into a nonwoven textile through carding and needle-punching. Its mouldable, breathable, and mould-resisting properties make it an excellent choice for building and automotive solutions.

-

Construction

Automotive -

GSM: 250

Thickness: 4mm

9. Post-consumer Textiles Recycling - needle -punch

Post-consumer waste is one of the toughest challenges in textile recycling, with its mix of colours, finishes, and unknown fibres. We have taken predominantly viscose textile waste and binder fibres, transforming them into a nonwoven textile using carding and needle-punching. This waste has gone through a defibration process that tears the construction apart to a higher degree.

The result is a vibrant, mouldable material, perfect for acoustic, interior, and packaging solutions.

-

Acoustic

Interior

Packaging -

GSM: 220

Thickness: 3mm

10. Pure WOOL & off-cuts from wool knitted cutting waste

Swedish wool is an underused resource with exceptional qualities, and we are here to change that. In addition to pure wool, this sample contains defibrated off-cuts from knitted wool cutting waste. The material is extra bouncy and highly resilient, perfect for cushioning or trapping air in insulation. Processed into a nonwoven textile through carding and needle-punching, it delivers superior insulation and fire resistance.

-

Filling or lining

Interior

Furniture solutions -

GSM: 300

Thickness: 4mm

11. Swedish wool - needle-punch

Swedish wool is a highly underutilised resource, known for its outstanding natural qualities. One of its key advantages is its exceptional bounce and resilience, which allow it to maintain its shape while suspending a large volume of air. This makes it particularly effective for insulation, as the trapped air enhances thermal efficiency. When processed into a nonwoven textile using carding and needle-punching techniques, wool offers superior insulation and excellent fire resistance.

-

Acoustic

Automotive -

GSM: 300

Thickness: 4mm

12. Selvedge Recycling

In the world of textile production, some waste is simply unavoidable—like selvedges from woven fabrics. We turn selvedge production waste into an opportunity. This sample consists of inherently flame-retardant fibres from selvedge waste and binder fibres, transformed into a nonwoven textile using carding and needle-punching.

The result is a vibrant, mouldable, and soft material, perfect for acoustic, interior, and packaging solutions.

-

Acoustics

Interior

Packaging

Decorating -

GSM: 260

Thickness: 4 mm

Connect with us to explore nonwoven.

Let us help you explore the possibilities of nonwoven technology—where texture, durability, and flexibility align with your vision. Together, we can explore the potential of nonwoven airlay and needle-punch materials, designed to inspire innovation and push boundaries.

Please fill out the form to place your sample order.